Our page uses cookies

We use cookies to personalize and enhance your browsing experience on our website. By clicking "Accept All", you agree to use cookies. You can read our Cookie Policy for more information.

Make Food Production Easier

Sign up

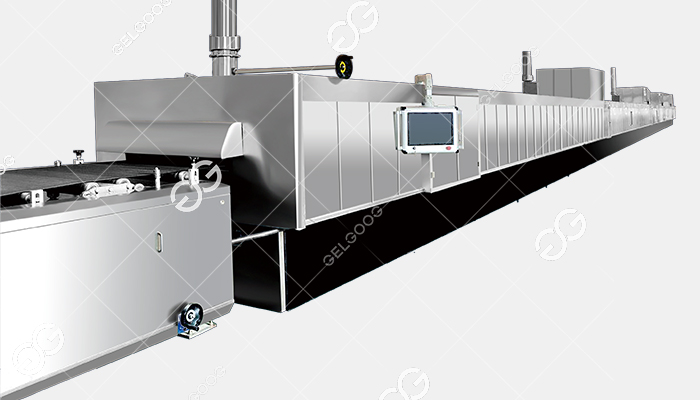

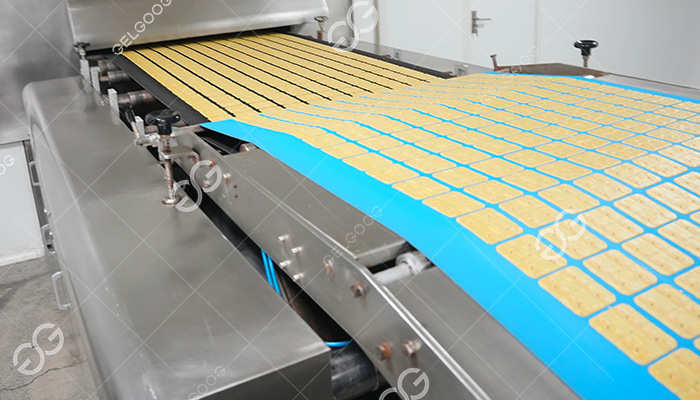

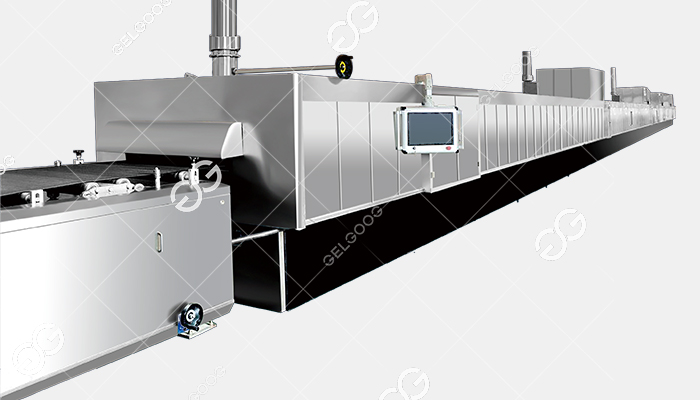

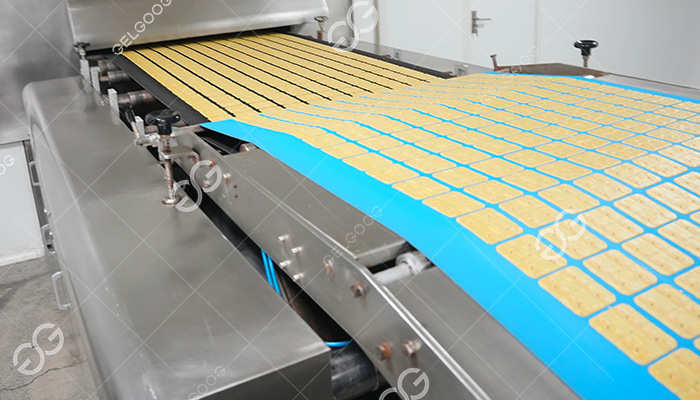

Our biscuit tunnel oven redefines industrial baking with a fusion of engineering precision and intelligent automation. Designed for non-stop, high-volume production, it supports 24/7 continuous baking across a wide variety of baked goods—from ultra-thin soda crackers to dense sandwich biscuits and filled pastries.⭐At the heart of the system is a multi-zone insulated baking chamber, typically divided into 3–5 independently controlled thermal sections, allowing real-time adjustment of temperature, air flow, and baking time to suit any recipe or texture requirement.⭐All while maintaining energy efficiency and consistent product color, texture, and moisture control. It offers unparalleled flexibility across product lines.

Dynamic recipe switching

Real-time process feedbac

Fault diagnostics and remote monitoring

<p>

High-Efficiency Tunnel Baking System Powerful and precise, our biscuit tunnel oven empowers high-volume baking with industrial-grade consistency. From delicate shortbread to dense sandwich biscuits, the multi zone oven delivers pinpoint control across 150–300°C, ensuring uniform coloring, crisp textures, and minimal deviation. ⭐ Modular heat zones – independently controlled for optimal bake per recipe ⭐ Up to 1000kg/h output – supports both large-scale workflows ⭐ Flexible fuel options – electric, gas, or infrared heating modules available ⭐ Seamless line integration – supports upstream forming and downstream cooling systems

Smart Control Meets Clean Engineering Redefining tunnel baking through digital intelligence and hygienic design. Our PLC touchscreen system ensures accurate real-time temperature tuning, recipe presetting, and fault alerts – enabling zero-compromise production, even under 24/7 operations. ⭐ Auto-adjust speed and heat based on product thickness and type ⭐ Intelligent alarms + remote monitoring for easy maintenance ⭐ Food-grade stainless steel build, with detachable parts for quick cleaning ⭐ Optional IoT modules for centralized production traceability

Scalable Solutions for Serious Biscuit Makers Whether you’re expanding a legacy factory or launching a smart central kitchen, our tunnel oven system adapts to your ambitions. From niche innovation to high-throughput mainstream lines, get the flexibility you need – without doubling your investment. ✅ One oven, multi-product capability – cookies, crackers, pastries, cakes, mooncakes, and more ✅ Custom dimensions – belt width, length, and zone count tailored to plant layout ✅ Global standard compliance – HACCP, ISO, CE ready ✅ Built to grow – supports integration with oil spraying, sugar sprinkling, and cooling conveyors

High-Efficiency Tunnel Baking System Powerful and precise, our biscuit tunnel oven empowers high-volume baking with industrial-grade consistency. From delicate shortbread to dense sandwich biscuits, the multi zone oven delivers pinpoint control across 150–300°C, ensuring uniform coloring, crisp textures, and minimal deviation. ⭐ Modular heat zones – independently controlled for optimal bake per recipe ⭐ Up to 1000kg/h output – supports both large-scale workflows ⭐ Flexible fuel options – electric, gas, or infrared heating modules available ⭐ Seamless line integration – supports upstream forming and downstream cooling systems

Smart Control Meets Clean Engineering Redefining tunnel baking through digital intelligence and hygienic design. Our PLC touchscreen system ensures accurate real-time temperature tuning, recipe presetting, and fault alerts – enabling zero-compromise production, even under 24/7 operations. ⭐ Auto-adjust speed and heat based on product thickness and type ⭐ Intelligent alarms + remote monitoring for easy maintenance ⭐ Food-grade stainless steel build, with detachable parts for quick cleaning ⭐ Optional IoT modules for centralized production traceability

Scalable Solutions for Serious Biscuit Makers Whether you’re expanding a legacy factory or launching a smart central kitchen, our tunnel oven system adapts to your ambitions. From niche innovation to high-throughput mainstream lines, get the flexibility you need – without doubling your investment. ✅ One oven, multi-product capability – cookies, crackers, pastries, cakes, mooncakes, and more ✅ Custom dimensions – belt width, length, and zone count tailored to plant layout ✅ Global standard compliance – HACCP, ISO, CE ready ✅ Built to grow – supports integration with oil spraying, sugar sprinkling, and cooling conveyors

| Dimensions(L*W*H) | 21000*2280*2180MM |

| Air Consumption (Gas Consumption) | 0.9m/m |

| Power | 2HP |

| Voltage | 380V |

| Size of Baking Plate | 40*60CM |

Please leave your specific needs, so that we can contact you promptly the first time. The price of the product needs to be based on your specific needs and configurations, please fill in the message form below to fill in your needs, or directly with our sales team, and we will contact you as soon as possible.

We value customer experience, not only providing professional solutions and trustworthy equipment but also providing customers with the whole process of service experience from demand to satisfaction. Transportation and packaging.

We offer our customers a variety of organizational and technical measures. Providing good technical service is an important part of GELGOOG's industrial management, which is conducive to improving the economic efficiency of our customers, as well as improving the quality of our own products and product structure, creating greater value for our customers.

In your message below, if you mention your food industry experience or specific requirements, we will contact you first and provide you with a free quote and process flow details.

Our

Locations

Our

LocationsService hotline: 0086-18538123076

Wechat/whatsapp: 0086-18538123076

E-mail: isle@gelgoog.com

Address: No. 1507, Hanghai East Road, Zhengzhou Free Trade Zone, Zhengzhou city, China

E-Mail

isle@gelgoog.com

E-Mail

isle@gelgoog.com

Contact

0086-18538123076

Contact

0086-18538123076

Whatsapp

0086-18538123076

Whatsapp

0086-18538123076

TOP

TOP

We use cookies to personalize and enhance your browsing experience on our website. By clicking "Accept All", you agree to use cookies. You can read our Cookie Policy for more information.