Our page uses cookies

We use cookies to personalize and enhance your browsing experience on our website. By clicking "Accept All", you agree to use cookies. You can read our Cookie Policy for more information.

Make Food Production Easier

Sign up

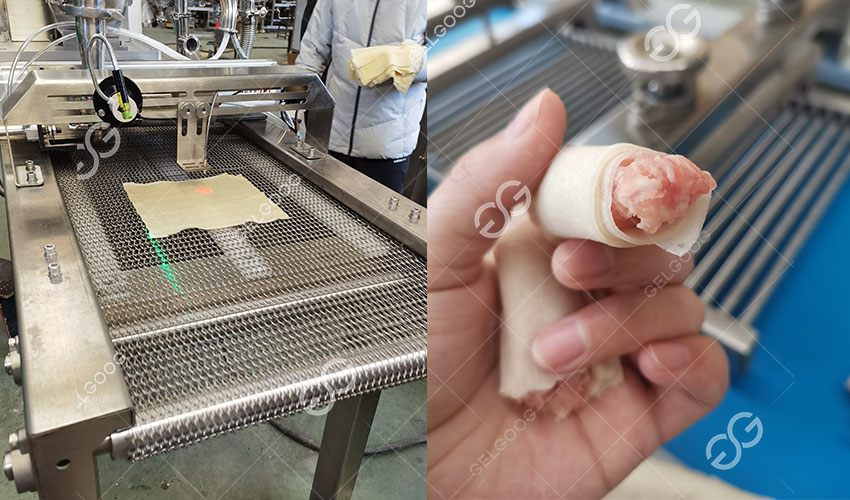

In today’s fast-paced food processing industry, production efficiency and product consistency are key to staying competitive. Spring rolls, a beloved traditional delicacy around the world, are no exception. As demand rises, so does the need for smarter and more efficient production methods. Our spring roll production line was developed to meet this demand—offering high efficiency, intelligent features, and full customization. No wonder it has become the go-to solution for clients across the globe.

1. Core Equipment: Simplifying Spring Roll Wrapper Production

Our spring roll wrapper machine is designed with multiple integrated functions to make operations easier than ever:

One-time forming technology ensures uniform size and thickness, which is critical for consistency in taste and appearance.

User-friendly and fully adjustable, allowing you to fine-tune the wrapper thickness and size based on your specific production needs.

Constructed entirely from food-grade stainless steel, the machine is durable, hygienic, and easy to clean or maintain.

Intelligent automation: The machine supports automatic folding, slicing, and counting, significantly reducing labor costs and increasing productivity.

2. Dual Heating Options with Precise Temperature Control

We understand different customers have different production setups. That’s why we offer two heating systems:

Electric and gas heating options, with adjustable temperatures between 110–140°C;

Electromagnetic heating combined with digital temperature control instruments ensures even and consistent heat distribution on the baking wheel surface, for perfectly cooked wrappers every time.

3. Fully Customizable: Thickness, Size, and Tray Design

Wrapper thickness adjustable from 0.3–2mm, achieved through fine-tuning the batter formula and the gap between the spray nozzle and baking wheel.

Custom tray and mold shapes tailored to your preferred wrapper size or spring roll style—whether traditional or innovative.

Premium materials: The roller is made from wear-resistant manganese-nickel alloy; all other key components are made from 304 stainless steel for long-lasting, hygienic operation.

4. Designed for All Business Sizes

Whether you are:

A large-scale food manufacturer looking to expand capacity,

A startup entering the spring roll market,

Or a workshop aiming to modernize your manual production,

Our production line can be tailored to your unique requirements. We provide scalable solutions to help you improve output, maintain consistent quality, and capture more market share.

A reliable production line is worth more than ten skilled workers.

By choosing our spring roll production line, you're not just investing in a machine—you’re investing in your product quality, operational efficiency, and brand reputation.

Contact us today for a tailored consultation. We’ll help you design a custom solution that fits your needs and sets you on the path to smart, high-efficiency spring roll production.

If you are interested in the machine, contact us

Email: isle@gelgoog.com

WhatsApp/Phone: +86 18538123076

E-Mail

isle@gelgoog.com

E-Mail

isle@gelgoog.com

Contact

0086-18538123076

Contact

0086-18538123076

Whatsapp

0086-18538123076

Whatsapp

0086-18538123076

TOP

TOP

We use cookies to personalize and enhance your browsing experience on our website. By clicking "Accept All", you agree to use cookies. You can read our Cookie Policy for more information.