Our page uses cookies

We use cookies to personalize and enhance your browsing experience on our website. By clicking "Accept All", you agree to use cookies. You can read our Cookie Policy for more information.

Make Food Production Easier

Sign up

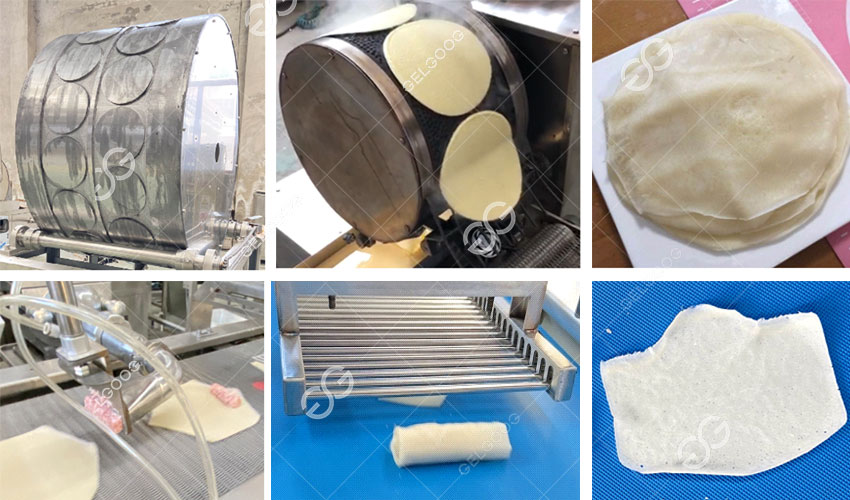

Elevate Your Spring Roll Production with Our Customized Production Line

In the era of globalization and rising living standards, the demand for food quality and taste has reached unprecedented heights. Among the plethora of culinary delights, spring rolls stand out as a beloved Asian delicacy cherished for their exquisite taste and nutritional richness. Choosing an efficient and reliable production line is paramount in the process of spring roll manufacturing. Our spring roll production line, distinguished by its outstanding performance and customizable features, emerges as your indispensable choice.

Let's begin by examining our spring roll wrapper machine:

1. Utilization of One-time Forming Principle: Ensures uniformity in the size and thickness of spring roll wrappers, thereby guaranteeing the quality of the final product.

2. Convenient Operation: The machine allows for easy adjustment of wrapper thickness and size according to mold specifications, catering to the production of various spring roll sizes.

3. Stainless Steel Construction: All components are crafted from stainless steel, ensuring a rational structure and facilitating straightforward maintenance, disassembly, and cleaning.

4. Additional Features: Apart from one-time forming, the machine can automate tasks such as folding, slicing, and counting, significantly enhancing production efficiency.

Our spring roll production line prioritizes user experience and customization needs:

1. Versatile Heating Options: We offer two heating methods - electric and gas - with temperature control ranging from 110 to 140°C. This allows for adjustment of wrapper thickness based on specific requirements, while ensuring uniform heating through surface temperature control via electromagnetic heating and temperature gauges.

2. Customized Tray Shapes: We can tailor the shape of baking trays to match the dimensions and shapes desired by the customer, accommodating diverse requirements.

3. Adjustable Thickness: The thickness of spring roll wrappers can be fine-tuned from 0.3 to 2mm, achieved through adjustments in batter formulation and gaps between the spray nozzle and baking wheel.

4. Premium Materials: We meticulously select materials, with rollers crafted from manganese, nickel, and other alloy materials to ensure durability and prolonged lifespan. Additionally, other components are made from high-grade stainless steel (304), ensuring both safety and hygiene.

In summary, opting for our spring roll production line guarantees superior quality and tailored services. Whether you operate a large-scale manufacturing facility or a small food processing unit, we stand ready to provide the most suitable solutions, enabling you to effortlessly produce delectable spring rolls that meet market demands and earn customer trust. We eagerly anticipate collaborating with you to usher in a new era of delicious spring rolls!

If you are interested in spring roll production, please don't hesitate to contact us. We are committed to meeting your requirements and devising tailored solutions for your spring roll needs.

Email: isle@gelgoog.com

WhatsApp/Phone: +86 18538123076

E-Mail

isle@gelgoog.com

E-Mail

isle@gelgoog.com

Contact

0086-18538123076

Contact

0086-18538123076

Whatsapp

0086-18538123076

Whatsapp

0086-18538123076

TOP

TOP

We use cookies to personalize and enhance your browsing experience on our website. By clicking "Accept All", you agree to use cookies. You can read our Cookie Policy for more information.